PRODUCTION

Our production process begins at the abattoir, where we meticulously prepare the casings according to our strict quality specifications. This initial step is crucial as it lays the foundation for the final products we offer.

Once the casings have been prepared, they are carefully cleaned at our dedicated facility in Downpatrick. This thorough cleaning process ensures that the casings meet the highest hygiene standards, making them safe and suitable for use.

After cleaning, we take two distinct paths with the casings. Some are salted and packed into barrels for export, allowing us to supply a global market with high-quality materials. Others are specifically selected for the sausage maker, ensuring that our products are crafted with the best casings available for optimal texture and flavour. This attention to detail is key to delivering exceptional results in the sausage-making process.

-

Employing soft tubes for stuffing the casing not only streamlines production but also enhances efficiency, ensuring a swift and seamless process.

-

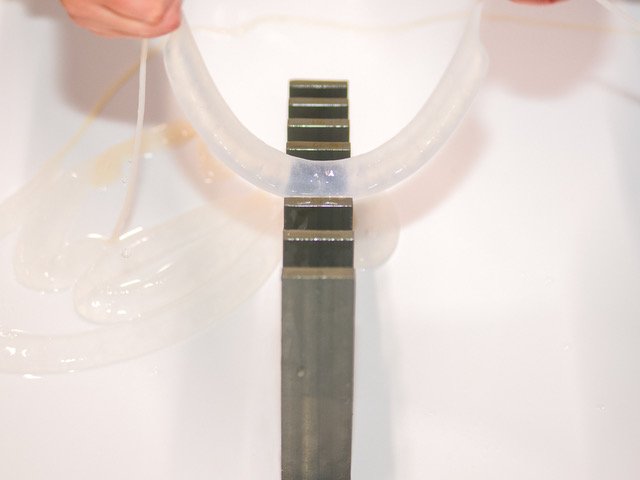

De-threading sheep casings on the finishing machine.

-

The comprehensive calibration service for sheep and hog casings ensures the highest quality and precision for your needs.